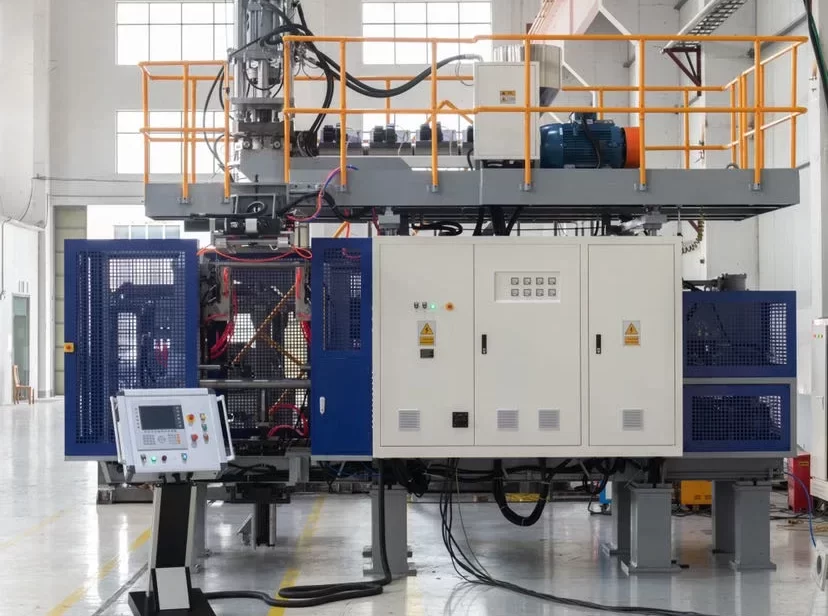

Blow molding service

Blow molding is the process used to make hollow, plastic products such as containers or bottles. These plastic products or parts are created by extruding a tube of hot plastic, called a parison, into an open mold. Compressed air forces the plastic outward into the shape of the mold. Once it is properly molded, the plastic is cooled and hardened. Finally, the mold is opened and the completed, blow molded product is removed. The blow molding process is highly complex and requires the expertise of professional designers and engineers. Please contact us with your questions; our team is happy to help guide you through the process.

Product description

Materials We Work With

- Acrylonitrile Butadiene Styrene (ABS)

- High Density Polyethylene (HDPE)

- Low Density Polyethylene (LDPE)

- Polypropylene (PE)

- Polystyrene

- Polyurethane

- Santoprene

- Kostrate

- K-Resin

Product Capabilities

- Large parts up to 5lb shot size

- Small parts 5 grams

- Multi-component parts (over molding and insert molding)

Mold Process Type

- Single cavity blow mold usually 70/75 aerospace aluminum.

- Multi cavity blow mold with beryllium pinch for longer tool life (mold life is in the millions of parts).

- We run air needle and blow pin blow molds.

- Molds that require inserts or over molded components are used.